- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

FAX: 86 371 65688109

1522533275 1360381889

1522533275 1360381889

dbelephant2007@hotmail.com

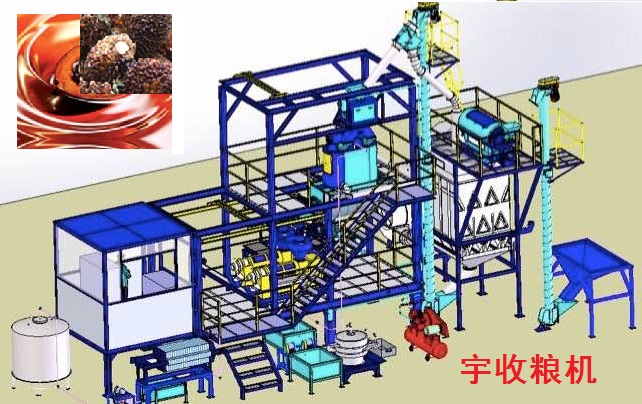

Palm oil mill

Crude Palm Oil (CPO) making line

The oil palm is the most efficient oil-bearing crop in the world, One mature palm tree could produce 100kg palm fruit, including to 45-50% palm kernel. only requiring 0.26 hectares of land to produce one tonne of oil.

It produces two types of oils; crude palm oil (CPO) from the pulp (fibrous mesocarp) and crude palm kernel oil (CPKO). from the kernels.

Although both oils originate from the same fruit, palm oil is chemically and nutritionally different from palm kernel oil. It is one of the only two mesocarp oils available commercially, the other being olive oil.

New technology:

the complete FFB adopts the dry process technology ,without any waste water for pollution !

Main data

Capacity: 2.0-90 tons / hour FFB

The rate of output oil: > 20% (To FFB)

Palm kernel recovery rate: 95%

By-product: Cake meal for cow feed; EF for the pellet fuel.

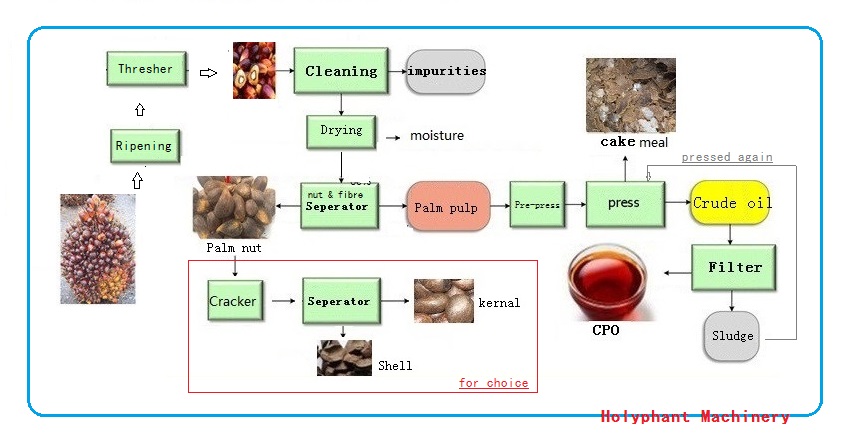

Flowchart

Main process

1.Raw materials storage section:

Fresh palm fruit bunch must be first measurement recorded by the pound into the plant, then unloaded to loaded fruit slopes and stored.

2.Ripping section:

The fresh palm fruit bunch are ripped under the nautal and our new technology.The purpose to prevent enzymes broken down, avoiding FFA content in oil further increase; pretreatment peel, prepared for the follow-up processing; pre-conditioning stone, reducing the damage kernel.

3.Threshing section:

The purpose of threshing is the oil palm fruit be separated from the fruit bunch through strong vibration, Threshing equipment is revolving drum thresher. The oil palm fruit separated be ejected then into the press section. Empty fruit bunch be ejected to the yard from the other side of the revolving drum, or shipped out from the plant as palm orchards slipcover to recycling use, or burning in the locale as fertilizer for agricultural land.

4.De-mesocarper and pre-pressing section

After drying ,The palm fruit quickly is carried out for Demesocarper,to separate to fruit pulp and nut.

The nut is conveyed into nut clearer process,the palm pulp is fed into screw cooker for heating . The pulp is fed into one screw press for pressing out some oil .

5. Pressing section:

Palm fruit pulp enter into continuous screw press for pressing,which is divided into two parts: crude oil, solid impurities mixture including to the cake . Crude Oil gutter inflow to oil purification section; press cake is conveyed into the fiber- recovery section.

6.Clarification section:

It adopts the vibrate sieve to remove out the big dregs,fibre from the crude oil .

then use the Plate filter to remove out the small dregs . After two steps the crude oil is very clearer.

7.Fiber recovery and separation section (for pressing):

This process adopts the centrifuge sieve to separate the nut and fibre and dregs.

The nut is for store after drying under vertical dryer,the firbre and dregs is for the fuel .

dregs is for the fuel .

8.Kernel recovery section:

The stone processes intenerate tempering before broken, the intenerating stone by the corrugated crusher be divided into two or more petal, kernel was released. The broken mixture enters into broken mixture separation system; separation system adopts two stage separation and claybath separation. Separation shell is sent to the warehouse for temporary storage, or as boiler fuel; the moisture content of separation kernel falls to below 7 percent through the hot air to dry. Dried kernel are sent to kernel storage warehouse for storing or for pressing PKO.

9. Biogas (Power) generator

The Shell and palm fiber as the fuel directly used for power generation, which can meet the electricity needs,not need the external power to supply for the project.

- Clicks: 0

- Add Time: 2018-12-22