- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

FAX: 86 371 65688109

1522533275 1360381889

1522533275 1360381889

dbelephant2007@hotmail.com

Cooking oil refinery

Technical Description:

The Cooking Oil refinery is to refine the crude veg oil,get rid of the deleterious impurity, then get the high qulity edible oil.

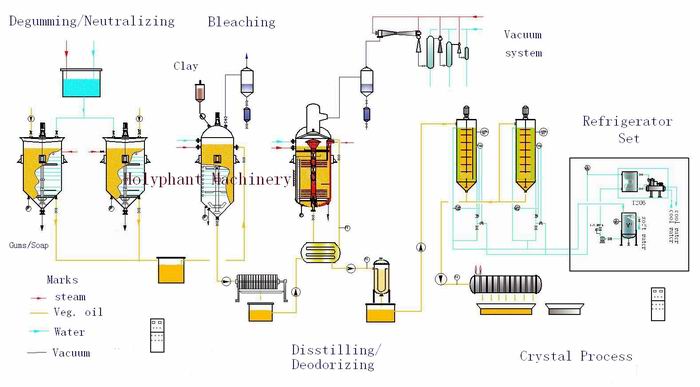

The process includes:degumming, neutralizing,bleaching, deodorization,dewaxing and so on.

Main equipment:

The refinery vessel, decolorizer vessel/tower, deodorizer vessel/ tower, filter ,steam boiler or conducting oil stove , steam jet pump, centrifugal pump, measurable pump, oil pump, water pump, water tower, electrical control cabinet,etc.

The refinery vessel, decolorizer vessel/tower, deodorizer vessel/ tower, filter ,steam boiler or conducting oil stove , steam jet pump, centrifugal pump, measurable pump, oil pump, water pump, water tower, electrical control cabinet,etc.

Applied To : All kinds of the crude veg oil, extracted from soybeans,cottonseeds, rapeseeds,maize embryo,rice bran, palm fruit ,etc.

Refinery Methods : mainly Chemical refinery and Physical Refinery

Physical refinery

Physical Refining is suitable for some kinds of crude oil with the less non-hydratable phospholipids and high FFA. It has the special characteristic than chemical refineing method.

Mainly including to the following steps.

1.Deguuming & Pre-bleaching

2. Dewaxing /Winterising /Fracnation

This is only for the several kinds of veg oil ,such as sunflower,cottonseeds,palm,rice bran,etc.

3.Distilling for neutralizing & bleaching,deodorizing

Special degumming

It is very necessary ,which remove out the non-hydratable and hydratable phospholipids in the crude oil . The gums content in the oil should be controlled for suitable for the next distilling process .Add the small quantity of acid or dilute alkali to the crude oil ,to change the non-hydratable phospholipids into hydratable phospholipids for easily being washed out .

Dry method degumming and pre-bleaching technology

1. It reduces the lost of neuter oil for 50%; saving the clay for 40-50% ,which improve the yield .

2. Energy-Saving and Environmental Protection technology .

This technology does not produce any waste water for saving more investment,so not any pollution.

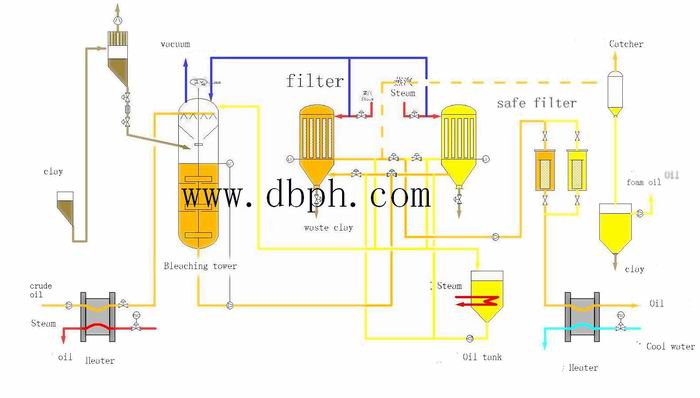

Bleaching

The Bleaching process is a physical process, where the impurities in the oil such as phospholipids, trace metals, pigment, decomposition products etc are removed with the help of an adsorbent under the high temperature and vacuum condition, Generally the active clay is used,if mixing into 5-10% active charcoal better to absorb pigment .

The Bleaching process is a physical process, where the impurities in the oil such as phospholipids, trace metals, pigment, decomposition products etc are removed with the help of an adsorbent under the high temperature and vacuum condition, Generally the active clay is used,if mixing into 5-10% active charcoal better to absorb pigment .

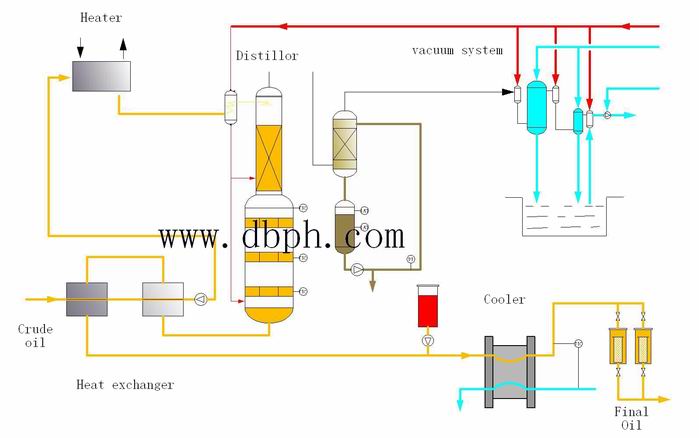

Distilling & Deodorizing

The oil is stripped under the high vacuum and high temperature condition . This process not only remove out the FFA and odiferous compounds,but also the reduces the color,decomposition of oil, peroxide value,trace metals etc.

The oil is stripped under the high vacuum and high temperature condition . This process not only remove out the FFA and odiferous compounds,but also the reduces the color,decomposition of oil, peroxide value,trace metals etc.

Features:

1.The high oil yield,low loss. 2.No waste water for prodution.

3.Fatty acid distillated quantity increase.

4.More suitable oil product of high acid value and low gum impurities.

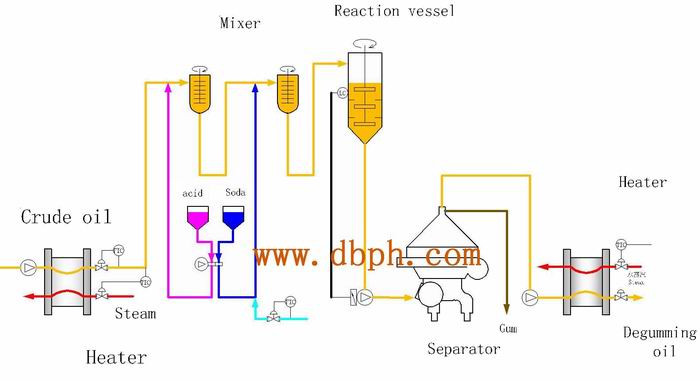

Chemical refining

It is widely suitable for small type refining mill,specially for the soy oil refinery.

In this process, the crude veg. oil filtered is added into the acid and NaOH for neutralization and degumming to separate FFA's, phospolipids and other impurities.

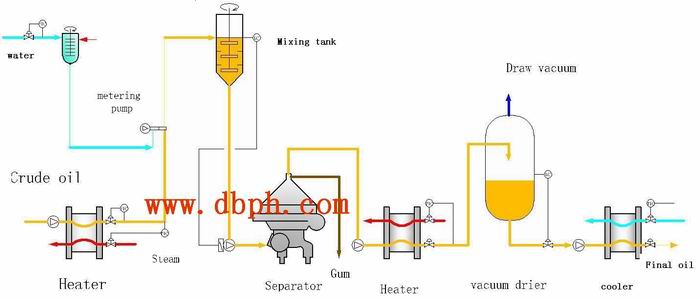

Water Degumming

To remove out the hydratable water washing method,wich is named Water Washing .

Use hot water to remove out the hydratable phospholipids . Degumming oil could be used for producing the No 3-4 Grade edible oil after Dehydration and desolventization.

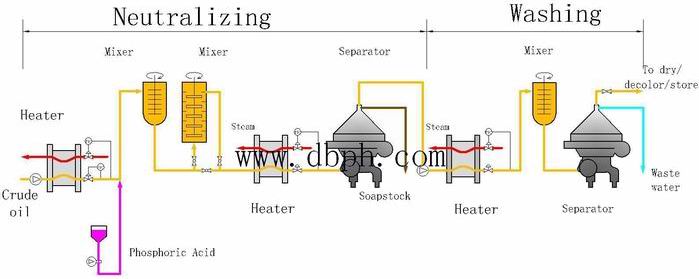

Neutralizing

To neutralize the free fatty acids (FFA ) of crude oil via adding the alkali ,the process transforms the FFA into soaps,then use the hot water to wash out the soap with the centrifugal separation.

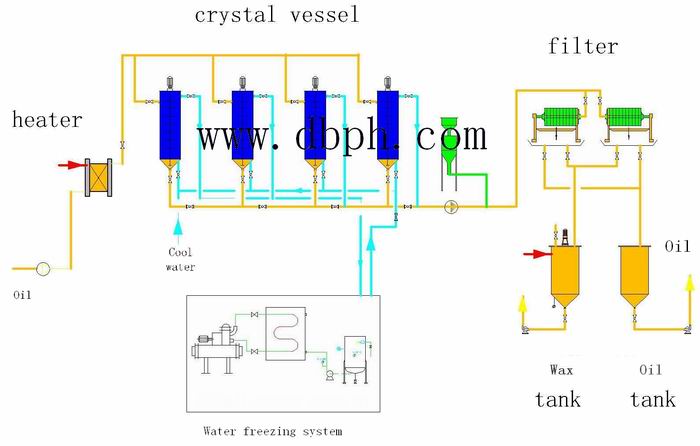

Dewaxing/winterization

Like the Sunflower, cottonseeds,Corn and Rice bran oil must to be dewaxed before consumption as it contains more wax. Also the wax makes the oil cloudy.the salard oil or high cooking oil must be the clearer and not exhibitcloudiness when stored in the refrigerator at low temperatures.

Like the Sunflower, cottonseeds,Corn and Rice bran oil must to be dewaxed before consumption as it contains more wax. Also the wax makes the oil cloudy.the salard oil or high cooking oil must be the clearer and not exhibitcloudiness when stored in the refrigerator at low temperatures.

The Oil with high molecular wax tastes not well and affact appetite, can not be digested and absorded,so it is necessary to remove it.

Batch refining

Small type cooking oil refinery line 20 tons Veg Oil Refinery

The Batch refining is the older method for refining vegetable oils,which is suitable for the small capacity , less than 20 tons .It is the low investment, easily operate and easy maintenance.

Main data

Suitable crude oil: kinds of crude veg oil

Capacity:0.5-20tons/day

Operator:2-4 persons

Flowchart