- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

FAX: 86 371 65688109

1522533275 1360381889

1522533275 1360381889

dbelephant2007@hotmail.com

Biodiesel

Biodiesel is typical "green energy resource", is made from soy and rapeseed oil crops, oil palm and pistacia chinensis bunge oil fruit, microalgae Oil aquatic plants and animal oil, waste edible oil as raw material. Developing biological diesel oil for sustainable economic and social development, Optimize energy structure, reduce pressure of environment has important strategic significance.

Compare with normal diesel, biodiesel is good for environment protection.

Introduce of technology

(for the example :rapeseeds oil)

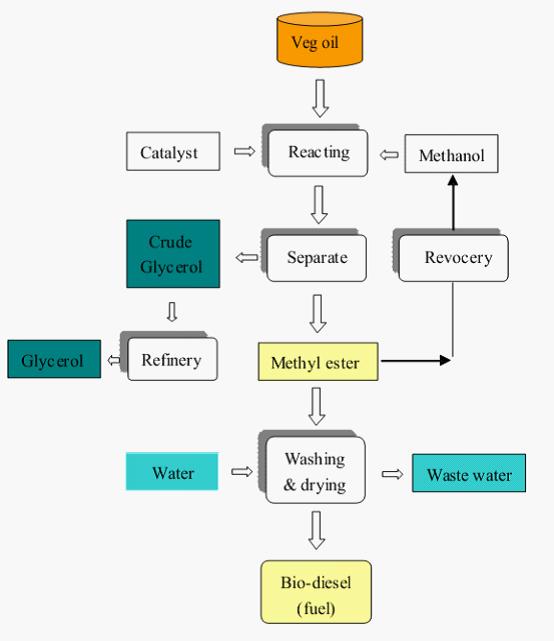

Main process

Twice time Reacting step

Rapeseed oil and methanol, catalyst in caustic soda existence condition happened methyl continuous change. After two level methyl ester reaction go to the water washing process,which get the pure Methyl ester.

Rape oil heated add into the methanol and catalyst on the first level reaction, parts of the fatty acid is changed into the methyl.This level of rapeseed oil was almost a methyl ester changed, The mixture of glycerol and methanol,methyl ester continuously is bringed out. Use one Centrifuge to separate the mixture of the first level reaction. Separate the rape oil/methyl ester and glycerol/methanol mixture. Methanol and glycerol in the subsequent process is recovery. In the second reaction of methyl further change the rape oil into methyl ester with adding the methanol and cyclast. Use the second Centrifuge to separate the two phase.

Twice time Washing step

In the first time use the normal soft water, the second use added acid water. Use the Centrifuge to separate washing water. Washed rapeseed oil methyl is dried via the vacuum,then use the heat exchange for cooling it .

The esterification reaction is one balance process,which the balance is relevant with the reaction temperature, pressure and catalyst .

This process can also be applied to other animal and plant oil methyl ester.

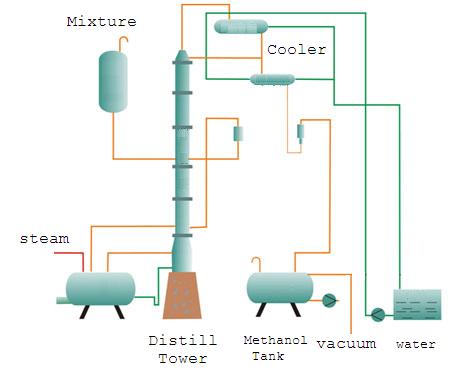

Recovery of methanol

Refinery of the Glycerin

Each production 10 tons of biological diesel , it can produce 1 ton of crude glycerin.

It is very necessary for refining the glycerin for increasing the yield .

The characteristic

Due to the reaction is divided into two steps, each reaction generated glycerin is centrifugal separation, methyl ester reaction degree can be more than 99%.

Energy-Saving and Environmental Protection bio-diesel technology

1.Dry method degumming and pre-bleaching technology

It reduces the lost of neuter oil for 50%; saving the clay for 40-50% ,which improve the yield .

2.Dry-washing to replace the water washing technology

It adopts MeSiO4 for the dry-washing catalyst to replace the water, to get the better quality bio-diesel than water-washing method.

This technology does not produce any waste water for saving more investment,so not any pollution.

HBIO series large-scale bio-diesel equipment ---Capacity: 30-500t/24h

|

Raw material pretreatment section

Raw material dehydration Washing for separation

|

|

Esterification section

|

|

Methanol recovery section Mechanical vacuum pump |

|

Advanced automatic controlling system |

|

All processes are controlled through PLC, reducing the blindness of artificial operation, improving the production efficiency, and ensuring the continuity of production and the consistent quality of products. |

|

Model |

HBIO-1 |

HBIO-3 |

HBIO-5 |

HBIO-10 |

HBIO-20 |

|

Capacity (T/D) |

0.2 - 1.0 |

1-3 |

5 |

10 |

20 |