- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

86 371 65688308

FAX: 86 371 67268997

1522533275

1522533275 zhaoqiany@hotmail.com

zhaoqiany@hotmail.com dbelephant2007@hotmail.com

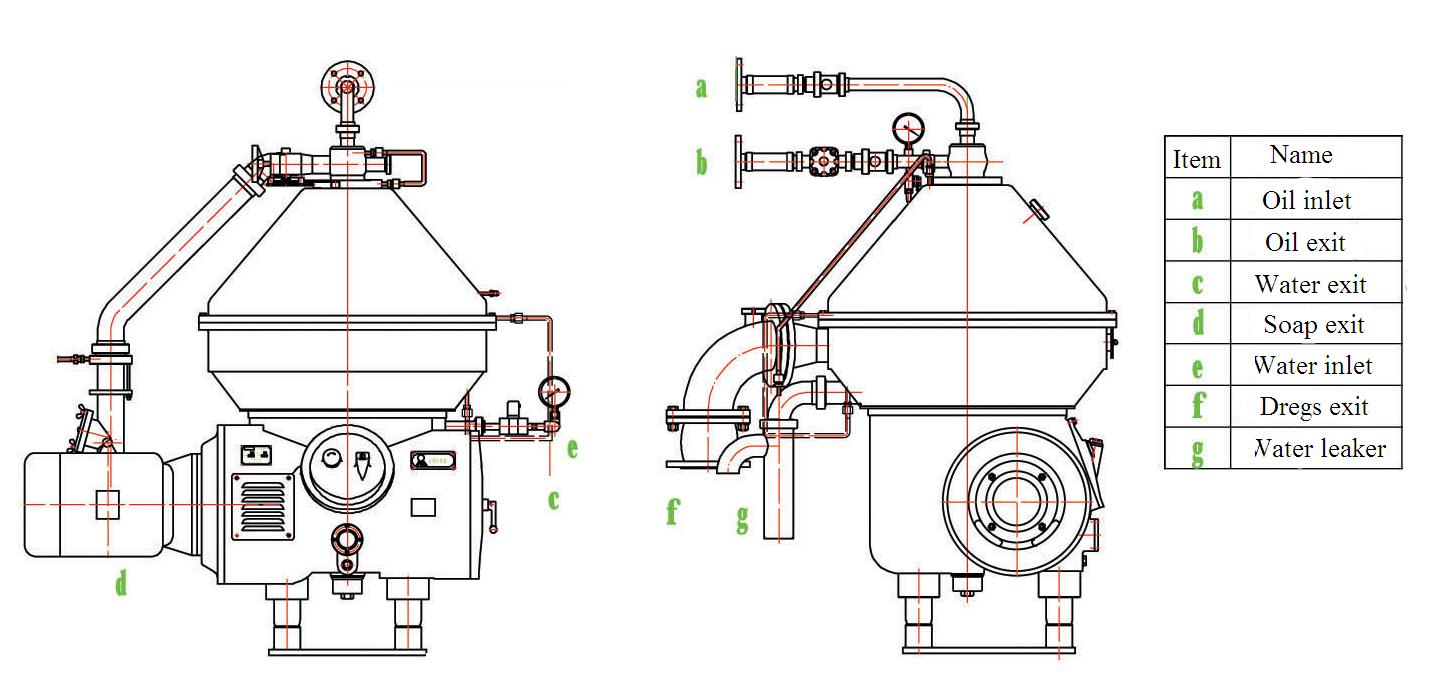

Disc Centrifuger

HDSHY System Oils and Fats Processing

Edible oil is one of the most important primary foods and therefore requires maximum quality. The quality of the final product depends on the refining method and the nature of the crude oil. Our centrifuge Separator offers a wide range of solutions designed to boost value in this respect, ranging from a separator with a daily capacity of 10 tonnes for operators of small oil mills right through to separators with capacities of more than 600 tonnes per day for large refineries.

Modern Processes for recovering oils and fats are characterized by the broad application of centrifugal clarifying and separating technology. The quality of the end product depends on the production process as well as on the nature of raw materials and products used.

Our centrifuge Separator provides various centrifugal separators, decanters that enable you to rapidly, efficiently and safely vary production to meet changes in your customers’ requirements and specifications.

Central Fields of application :

Degumming , Neutralisation ,Washing ,Winterisation , Fractionation ,Clarifying pressed distillate ,Oil and fat recovery

Main Fields of application:

Soybean oil,Rapeseed oil, Sunflower oil,Animal fat,Cottonseed oil,Corn oil, Fish oil, Palm oil, Rice bran oil

HDSHS system Biodiesel Process

Biodiesel, a kind of renewable fuel resource, is widely available. Now, a new trend of utilizing biodiesel resources is being raised. Compared with mineral diesel oil, it has such features as low sulfur content, low pollution emission, good renewability and excellent biological degradability etc. Therefore, it has wide development prospect.

Biodiesel is obtained by means of the socalled transesterification process. This is a chemical reaction, which replaces one type of alcohol in a given ester with another using methanol. As a result of this transesterification, the end product has a clearly lower viscosity than the untreated oil and can therefore be used as a fuel, with only minor adjustments to the engine. Biodiesel can be mixed in any ratio with mineral oil diesel.

Centrifugal separators can be used in the following process stagesin virtually all of the following:

■ Separation of methyl ester and glycerine / catalyst / soap / methanol

■ Washing of methyl ester

■ Separation of fatty acids from glycerine

■ Separation of salts from glycerine

- Clicks: 0

- Add Time: 2013-3-24