- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

86 371 65688308

FAX: 86 371 67268997

1522533275

1522533275 zhaoqiany@hotmail.com

zhaoqiany@hotmail.com dbelephant2007@hotmail.com

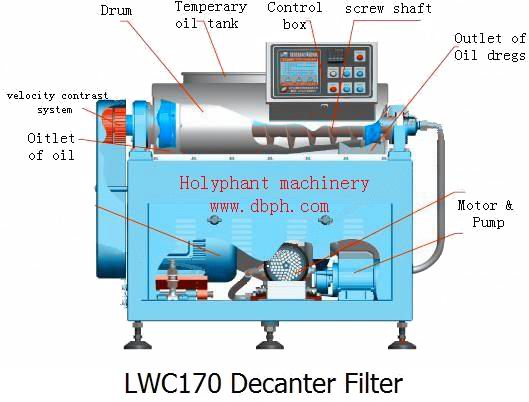

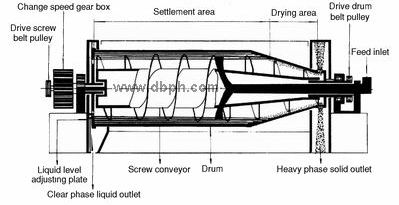

LW Decanter Filter

|

Model |

Drum size |

Drum Speed |

velocity contrast (r/min) |

Motor |

Capacity (m3/h) |

Weight |

Overall Dimension |

|

LWC170*600 |

Ø170*600 |

4800 |

10-30 |

3 |

0.3-0.5 |

450 |

1000*1100*1000 |

|

LW220×600 |

Ø220*600 |

5000 |

4/5.5 |

1-5 |

950 |

1545×1930×774 |

|

|

LW350×900 |

Ø350*900 |

3500 |

7.5 |

2-10 |

2207 |

2730×1885×1035 |

|

|

LW350×1200 |

Ø350*1200 |

3600 |

11/9 |

3-12 |

1810 |

2442×2113×1065 |

|

|

LW350×1500 |

Ø350*1500 |

3500 |

15 |

5-15 |

2650 |

3470×1785×1055 |

|

|

LW450×750 |

Ø450*750 |

2500 |

15 |

5-25 |

1735 |

2140×1450×700 |

|

|

LW450×1600 |

Ø450*1600 |

3200 |

37+11 |

6-30 |

2555 |

2670×1920×905 |

|

|

LW450×1900 |

Ø450*1900 |

2900 |

55+15 |

7-30 |

4200 |

4600×1200×1293 |

|

|

LW600×1800 |

Ø600*1800 |

1300 |

45+18.5 |

10-50 |

2500 |

2345×2005×928 |

*It is suitable for separating three-phase material (light, liquid, heavy liquid and solid)

- Clicks: 0

- Add Time: 2013-3-4