- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

FAX: 86 371 65688109

1522533275 1360381889

1522533275 1360381889

dbelephant2007@hotmail.com

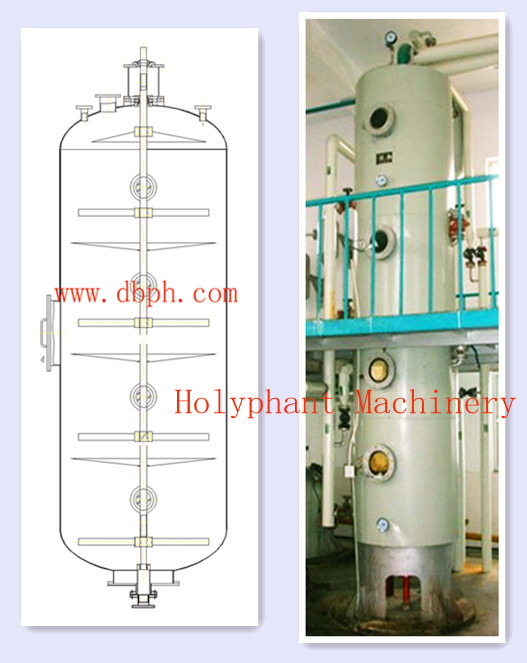

Decolorizer tower/Bleaching tower

Introduce

The system Bleaching tower mainly used for oil bleaching, with porous activated clay as the absorbent, under the condition of vacuum, absorbing and removing pigment and other impurities in the oil to achieve the objective of the removal of the pigment , meanwhile also to remove the micro-tablets and soap colloidal substances and trace metals, reduce oxides and two oxide content, which created the favorable conditions for further processing oil.

The bleaching tower adopts circulation steam mixing technology, whose advantages are:

1. Advanced steam mixing technology, excellent stirring results, mixed evenly, good decolorizing effect and the strong adaptability

2.In the absence of mechanical agitation, good equipment sealing performance, and no power consumption, stirring uniform and effective to avoid oil movement short circuit in the tower, concise efficient structure, operation and maintenance is very convenient, no need to replace wearing parts, and complete machine weight and load of tower Lower, is not high to the foundation request, the control arrangement is reasonable, easy to install.

3. Scaling tower is not easy, easy cleaning. Long life,low cost.

4.The liquid Level controlling device is installed, to ensure working continuous, safe operation ,make the human factors reduce to a minimum.

Model & Spec

|

Model |

Capacity (t/d) |

Tube Dia.(mm) |

Heigh of oil line |

Working Temperature(℃) |

Working Vacuum(Mpa) |

|

|

3 Layers |

4 Layers |

(mm) |

||||

|

HTST-80 |

20 - 30 |

30 - 50 |

Φ800 |

550 |

≤120 |

≤ - 0.096 |

|

HTST-100 |

50 - 70 |

70 - 90 |

Φ800 |

700 |

||

|

HTST-120 |

90 - 120 |

120-160 |

φ1200 |

850 |

||

|

HTST-140 |

140-190 |

190-250 |

φ1400 |

1000 |

||

|

HTST-160 |

180-250 |

250-330 |

φ1600 |

|||

|

HTST-180 |

240-300 |

300-450 |

φ1800 |

|||

|

HTST-200 |

350-450 |

450-600 |

φ2000 |

1200 |

||

|

HTST-220 |

450-500 |

600-650 |

φ2200 |

|||

|

HTST-240 |

500-650 |

650-900 |

φ2400 |

|||

|

HTST-260 |

650-800 |

900-1200 |

φ2600 |

1400 |

||

|

HTST-280 |

800-1000 |

1000-1500 |

φ2800 |

|||

- Clicks: 0

- Add Time: 2012-11-4