- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

FAX: 86 371 65688109

1522533275 1360381889

1522533275 1360381889

dbelephant2007@hotmail.com

Veg oilseeds Pressing / Pre-pressing & Extrusion Technology Equipment

Oilseeds Pressing equipment (10-100t/d)

Siever/Roaster/Crusher parts Pressing / pre - pressing (50-2,000t/d)

Rice bran/Soy Extrusion process crude oil filter

Technical description:

The process is for pretreatment for removing out the impurities from the vegetable oil materials. These impurities are generally referred to as organic and inorganic impurities. The organic impurities include the stem leaf, cord, chemical fibers, velveteen and their seeds. The inorganic impurities, however, sometimes mean soil, dinas and metal.The vegetable oil processing industry involves the extraction and processing of oils and fats from vegetable sources.

The main Technical process

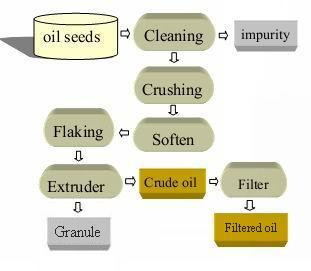

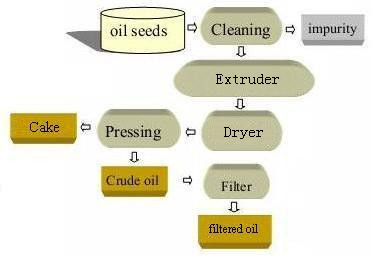

Pressing/Pre-pressing technology Crushing & Extrusion technology

The new technology

Recently In order to overcome the shortcoming of the poor quality protein of the cake and meal from the pre-pressing & solvent extraction process,we develop the new processing technology,these technology also could get the high quality crude oil.

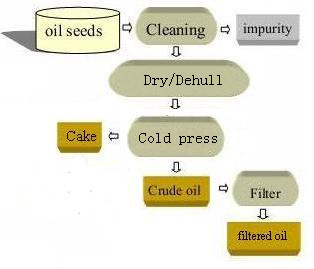

Extruding & Pressing Technology Cold Pressing technology

The extruding & Pressing Technology

It adopts the extruder to replace the traditional steam cooker vessel,to heat the seeds in shortly time, to make the oil cell expanding, keep the protein not destroyed , to get the good quality cake for the animal food .

The advantage with extruding-pressing method:

1.The crude oil quality is higher. The phospholipids of crude oil (150 ppm) is lower than cooking-pressing method (500-700 ppm). Also the better original oil color. The final oil is not required to refining. The final oil is 100% green edible oil .

2.The final oil yield is higher, about 98%, the residue oil of cake could be controlled to 4-5%.

The protein denaturation is less. The protein is destroyed small because of the shortly time heating (20s or so) in the extruder,so the protein is high quality for animal food or raw materials of human food .

3.The life of oil press is longer, also improve the capacity 50% more.

4.Energy consumption is less than cooking-pressing method. The extruder only requries the less steam than steam cooker .

5.Save the investment and working cost . Not require to use the solvent extraction process with the less oil in cake.

The main machines

Includes to the husking, cleaning, crushing, and softy & Roasting, pressing or extrusion and crude oil filter,etc.

The equipment is optimizedly composed of thesifter/screener, crusher, flaker,extruder,steamer,oil press,oil filter,boiler,related conveyor, and electrical control cabinet.

Suitable for the following oil seeds / oil materials.

The rapeseed/canola, peanut kernel, soybean, olive, walnut kernel, maize germ, rice bran, tea-seed, sallow thron seed, china berry seed, Rubber seed, china pepper seed, tomato seed,watermelon seed, grape seed, flax seed, Oenothera seed, pepper seed, castor seed, orange seed, cocoa bean, coffee bean, perilla, almond kernel, peach seed kernel, etc.

Input seeds : 5-1000t/d

The complete pretreatment equipment is applicable to different scale investment project of 5t-1000t per day for the choice .