- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

FAX: 86 371 65688109

1522533275 1360381889

1522533275 1360381889

dbelephant2007@hotmail.com

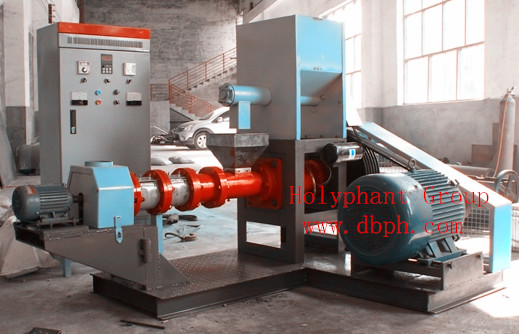

Oilseed extruder

Dry Extruder

General Description

It can be used for the expansion of rice bran, soybean, maize, rice powder and feed, kinds of grain extruding ,etc. It's appliable for the production of oil factory, rice factory, soybean protein factory, feed factory, etc.

The machine is of big production capacity, low power consumption. After extruding, ricebran can keep fresh for two months, the extraction yield can be 30-45% higher, residual oil in extracted dry meal less than 1%, the protein content, color both better than granulating-drying-extracting process. After extruding, soybean can be deodorized, urea enzyme in soybean can be passivated, the extraction yield can be 45-50% up, the residual oil content in meal less than 0.8%, the protein content and color both better than drying-extracting process.

Extruding Principle

By squeezing, rubbing, shearing forces of pressing worms of unequal thread pitches in the extruding cage, the mechanial energy is converted into heat energy, forms certain pressure and temperature in the extruding cavity, from the outlet die head, the extruded material spray out and inflated .

|

model |

HPLG-100 |

HPLG-120 |

HPLG-135 |

HPLG-160 |

|

capacity |

400~600kg/h |

700~800 kg/h |

1.0~1.5t/h |

1.5~2.0t/h |

|

motor |

Main motor 22kw feeder 1.1kw |

Main 30/37kw |

Main 45/75 kw |

Main 75/90 kw |

|

size (mm) |

1550×1780×1230 |

1950×1810×1260 |

2150×1900×1280 |

3000×2600×2000 |

|

weight |

900kg |

1200kg |

1680kg |

1800kg |

Wet Extruder

General Description

The machine is applicable for the extruding of low oil content crops such as rice bran and soybean or pressed cake before solvent extraction, is an ideal production process for the purpose of reducing equipment investment, raising production, reducing energy consumption and improving product quality of oil plants worldwide.

The oil material is squeezed, heated, sheared and rubbed in the extruding cavity of the machine, and mixed,

steamed,

gelatinized by injected direct steam, the pressure in extruding cavity will reach 1.4-4.0 MPa, the temperature reachs 110-120℃, at the die head outlet suddenly reduce to normal pressure and

temperature, the steam vaporizes abruptly, oil in seed cell run outside then, and extruded material with

numberless minus holes and cracks got.And because of such extruding effects, the permeating of solvent through cells and permeating of oil out from cells both become easier, so the extraction and desolventizing

process both get more efficient, the unit weight of material is raised about 30% , so the production capacity of extractor is also raised. The stay period of

material in the extruding machine is less than 30 seconds, so the damage of the content of material is little, which

helps the protection of the quality of material.

Main type & Spec

|

Model |

HPLS-120 |

HPLS-135 |

HPLS-160 |

HPLS-200 |

HPLS-300 |

|

Capacity (T/D) |

Rice bran:20 - 30 Corn:40 - 50 |

Rice bran:30 - 40 Soybean:40 - 70 Corn:50 - 80 |

Rice bran:50 - 80 Corn:80 - 150 |

Rice bran:80-150 Corn:150 - 300 |

600-1200 |

|

Power (kw) |

main motor:30/37 feeding motor: 1.1 Conditioner: 2.2 |

main motor: 37/55 feeding motor:1.5 Conditioner: 2.2 |

main motor: 55/90 feeding motor:2.2 Conditioner: 3/4 |

main motor: 55/75/90 feeding motor: 3/4 |

main motor: 132/160 feeding motor: 4 |

|

Diameter of screw |

100mm |

135mm |

160mm |

200mm |

300mm |

|

Size (mm) |

2800×1800×2000 |

3000×2200×2100 |

3700×2800×2800 |

4900×3260×2800 |

6218×1280×1700 |

|

Weight |

1.3-1.4 ton |

2-2.1 ton |

2.5 ton |

3.2 ton |

4.2 ton |

- Clicks: 0

- Add Time: 2015-4-10