- Pressing/Pretreatment

- - Veg. Oil Mill Equipment

- - Special Oil&Fat Technology

- - Single Machine Series

- => HPYL series oil press

- => 6YL series Oil Press

- => Combine Oil Press

- => Big Scale Oil Press

- => Cold Oil Press

- => Hydraulic Oil Press

- => Spare parts

- => Oil Filter

- => Cooker/Roaster

- => Dehuller/Peeler

- => Flaker/Crusher/Extruder

- => Sifter/Destoner

- => Other Accessory Mahcinery

- Solvent Extraction Technology

- Veg Oil Refinery Equipment

- Other oil & fat technology

- Silo/Oil tank/Steel warehouse

- Filling, Measuring Machine

- Veg oil,additive,lab instruments

FAX: 86 371 65688109

1522533275 1360381889

1522533275 1360381889

dbelephant2007@hotmail.com

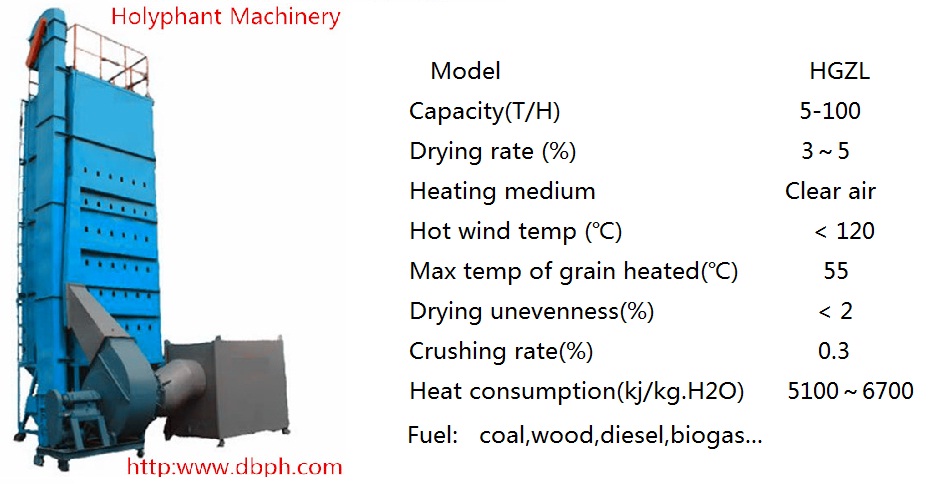

Grain Dryer

Roll Roaster

Introduction:

Suitable for roasting/drying different oil-materials, such as rapeseed, peanut, soybean, sesame seeds, cottonseeds, coconut, palm, olive, etc.

6GT Series closed rotary roaster is a new roasting machine for food and oil plant. It is developed by our experience of oil machine manufacture for many years based on home and abroad advanced technology.

Main features: reasonable structure, temperature meter, easy operation and high capacity. Because the roaster is closed, so it can control the heat to go out and achieve the steaming and roasting function, speed up the roasting seeds.

The other advantage is continuous turning work, materials roasted turned constantly, make its surface uniformly touch with pan area and avoid that flat pan roasting seeds not uniform and flammable and scorched, so it develops the oil output and oil quality.

Structure and principle:

The machine is mainly including to the machine frame, hopper, cylinder, block fire cover etc, the motor drives the gear shaft by the V-belt, the gear on the gear shaft drives the big gear on the cylinder to run; then the cylinder rotates continuously and uniformly, the materials are fed into the cylinder to be roasted.

Fuel: coal,wood,electricity,LPG,etc for the choice .

Main data:

|

Type |

6GT-400 |

6GT-700 |

6GT-1000 |

6GT-1500 |

... |

|

Cyclone (mm) |

¢400 |

¢700 |

¢1000 |

¢1500 |

|

|

Capacity(kg/h) |

80-100 |

150-200 |

300-500 |

500-1000 |

|

|

weight(Kg) |

150 |

310 |

500-800 |

800-1200 |

|

|

power(Kw) |

0. 75 |

1.5 |

2.2 |

2.2-3 |

|

|

Fuel |

Coal,wood,biomass briquette,gas,electrictiy |

||||

GTL-Continuse Roaster

|

Type |

Roasting capacity |

Drying capacity |

Roasting temperature |

Roasting time |

Drying Time (%) |

|

GTL-400 |

3~4 |

6~8 |

100~700℃±5 |

15~30 |

8~25 |

|

GTL-500 |

5~8 |

10~16 |

100~700℃±5 |

15~30 |

8~25 |

|

GTL-600 |

8~12 |

16~24 |

100~700℃±5 |

15~30 |

8~25 |

|

GTL-700 |

12~16 |

24~32 |

100~700℃±5 |

15~30 |

8~25 |

|

GTL-800 |

18~24 |

36~48 |

100~700℃±5 |

15~30 |

8~25 |

|

GTL-1000 |

30~40 |

60~80 |

100~700℃±5 |

15~30 |

8~25 |

|

GTL-1200 |

45~60 |

90~120 |

100~700℃±5 |

15~30 |

8~25 |

|

GTL-1500 |

65~80 |

130~160 |

100~700℃±5 |

15~30 |

8~25 |

HRHG system Conditioner

Main type and Spec.

|

Type |

HRHG120 |

HRHG140 |

HRHG160 |

HRHG180 |

HRHG200 |

|

Capacity(t/d) |

50 |

100 |

200-250 |

300-350 |

400-500 |

|

Motor(kw) |

3 |

4 |

5.5 |

7.5 |

11 |

|

Working pressure (MPa) |

0.4 |

||||

|

Weight (T) |

6.5 |

8.5 |

12.5 |

15.5 |

18 |

|

Diameter of roller (m) |

1.2 |

1.4 |

1.6 |

1.8 |

2.0 |

|

Roll speed (rpm) |

1-4 |

1-3 |

1-2 |

||

|

Outside (m) |

6*1.9*1.9 |

5.9*2.1*2.1 |

8.2*2.25*2.3 |

8.5*2.46*2.6 |

8*2.7*2.8 |

|

|

|

||||

|

Type |

HRHG220 |

HRHG240 |

HRHG250 |

HRHG260 |

|

|

Capacity (t/d) |

600-700 |

800 |

900-1000 |

1200 |

|

|

Power(kw) |

11 |

15 |

|||

|

Working pressure (MPa) |

0.4 |

||||

|

Weight (T) |

22 |

23.6 |

25 |

27 |

|

|

Diameter of roller (m) |

2.2 |

2.4 |

2.5 |

2.6 |

|

|

Roll speed (RPm) |

1-2 |

||||

|

Outsize (m) |

10.4*2.9*2.8 |

10*3*3.2 |

11*3.2*3.3 |

11*5.3*3.4 |

|

Vertical grain dryer

- Clicks: 0

- Add Time: 2015-10-22